|

Getting your Trinity Audio player ready...

|

In this article, we will focus on the production of energy storage batteries, specifically LiFePo batteries4 (LFP). For renewable energy storage, this technology will play an important role as it is a long-life and safer cell technology than other lithium cells while maintaining a high energy density.

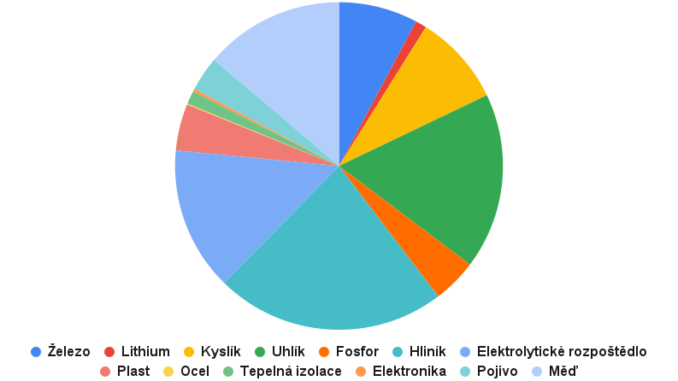

For the production of an LFP cell, the following materials are required: lithium, iron, polymer (phosphorus, oxygen), carbon, copper, aluminium, electrolyte and materials for the outer shell of each cell. In the pie chart below you can see the proportion of each material for the production of one cell:

The ratios may vary depending on the size of the cells or how they are used. The chart shows that the largest proportion of the cell content is aluminium and copper, which form the collector parts for dissipating the electric current, and aluminium usually also forms the casing for easy dissipation of excess heat. The negative electrode (cathode) is coated with carbon. The positive electrode (anode), on the other hand, is encased in a phosphate structure containing iron together with lithium ions. Between each electrode is a polymer membrane. The anode and cathode are then encased in an electrolyte.

The detailed composition of each material is better illustrated in the figure above.

According to the structure of the LFP cell, it is therefore clear that aluminium and copper will be the most desirable metals for the production of LFP batteries in the coming years. Which does not bring much change from the current needs and the recycling process of these metals is already well mastered. On the other hand, there will be an increased demand for high quality carbon or phosphate structures, where the development of nanotechnologies in their folding can be expected. Lithium is only present to a small extent. However, it is more difficult to obtain because it is highly reactive with oxygen and therefore more difficult to extract. It is obtained either by mining lithium salts or lithium ore. Recycling is also more difficult and requires more complex technologies.

Source: Firstphosphate, Solacity, LP_-_MSDS_-_LiFePO4.pdf (liteplan.com), (PDF) Paper No. 11-3891 Life-Cycle Analysis for Lithium-Ion Battery Production and Recycling (researchgate.net)

Přidejte odpověď

You must be logged in to post a comment.